Metal Scrap Chopper Knives

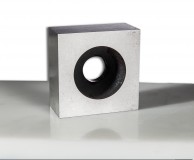

Come to IKS with your most demanding applications. We have been making scrap chopper blades for over half of a century, and have the requisite knowledge and necessary skillset needed to engineer the best scrap chopper knife for your application. We have made radial style, paddle style, and helical style chopper knives. To ensure that the proper materials are selected for the knife, each of these different styles require that we evaluate the customer and the materials to be processed. We then must be sure that the correct hardness is being used as well, especially since hardness is one of the most critical attributes for a scrap chopper knife. Our applications engineers use their many years of experience in order to determine that the correct hardness is selected for each order of scarp chopper knives produced.

With the growth in Advanced High Strength Materials, IKS has become a leader advancing the use of specialty tool steels to increase blade toughness and blade life. Customers of IKS working with our sales and engineering staff have seen blade life increase in some cases ten-fold. Contact an IKS product manager to have your application reviewed to see what we can do to improve your blade performance.

Click here to download instructions for typical scrap chopper knife grinding.

Click here to download our Metalworking product offerings.

Product Gallery